From Concept to Completion: Navigating the Stages of OEM Machine Build Projects

When you’re dealing with unique products, one-size-fits-all machinery simply won’t do. Opting for off-the-shelf machines and equipment could hinder your operational process, resulting in mistakes and product defects that reduce your profitability. Fortunately, you can find the exact solutions you need with OEM machine builds.

What Are OEM Machine Builds?

OEM stands for ‘Original Equipment Manufacturer,’ and machine builds are the mechanical solutions they’ve created for their clients. These manufacturers, like our team at Echo Automation, take your specific goals and obstacles into account when designing, creating and using custom machine builds. OEM solutions are used across a variety of industries, from automotive to electronics.

Essentially, OEM builds are custom machines that are designed and built for very specific purposes. They are meticulously tailored to a client’s operational needs, rather than being cookie-cutter solutions that are meant for general customers.

Custom OEM machine builds allow complete control over every part of your equipment. You can work with our specialists to integrate different features, customise performance and solve complex workflow problems so you get machinery that’s perfect for you.

Navigating The OEM Build Process

As you can imagine, creating custom solutions is a complex process that must be handled with skill and care. Where do you start when you work with our builders?

Step 1: Having A Consultation And Creating Concepts. The very first step in the process is to understand where you are, what you want and what you need from us. We will have a consultation so we can better understand your situation.

You may know what you want to achieve, but you may not know how to reach your goals. We start by meeting with you to highlight the following and more:

- Your Overall Goals. What is the main objective you are trying to fulfil? This could be to create machinery to efficiently create products to your exact specifications, to improve safety by automating processes and so on. We will highlight your specific goals so we know what we are working towards.

- Potential Obstacles. All projects come with some kind of risk or complication. We will discuss any potential obstacles, like budget constraints, safety concerns, etc.

- Your Involvement. What is your role in the development process? Of course, we are creating something for your specific purposes, so we want your input. But we will take the reins when it comes to designing and building the machinery itself. We must highlight your involvement in the project so you know what you’ll need to do.

- Timeline. We will go over the entire timeline of the project so you understand our workflow.

Step 2: Designing And Engineering The OEM Machine Build. Once we have everything sorted, we can begin to design the machinery itself. We utilise modern tools like engineering software and 3D models to gain insights into potential designs and the best possible build for your needs.

While we do this, we will keep all of your concerns in mind. This could include your budget, maintaining accuracy for your products and future-proofing the build. Our team works hard to select materials and create components that will last a long time while staying accurate and efficient.

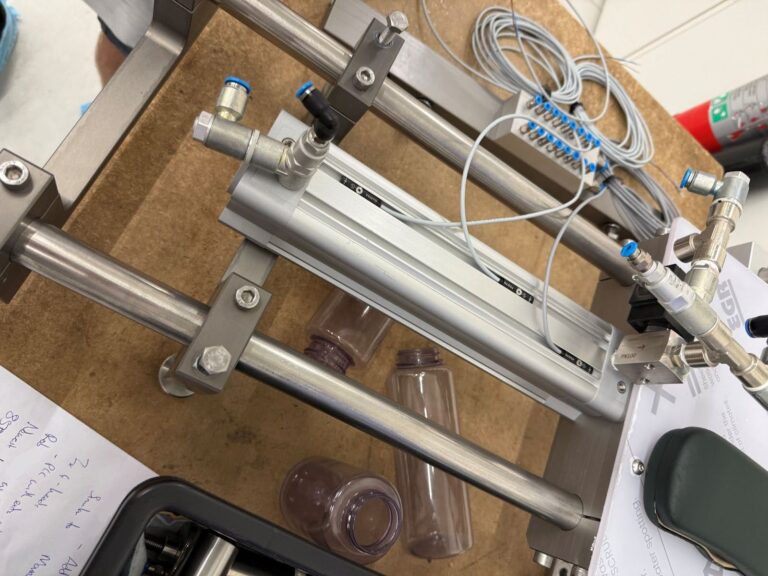

Step 3: Creating A Prototype. A major question you may have during the OEM machine build process is, “Will it actually work in my facility?” The idea of having a specialised machine just for your exact purposes sounds like a dream, so it’s natural to be worried about the outcome.

This is why we create a prototype to test for your purposes. This way, we can identify issues and refine movement to maximise speed, safety, efficiency and software integration. This lets you give feedback based on what you see, and allows us to fine-tune our results.

Step 4: Manufacturing And Assembling The Final OEM Machine Build. Once we’ve worked out all the issues and considered all improvements, we will create the machine itself.

We will stay in contact with you, ensuring you know how far along your machine is and when it will most likely be completed. Although delays can occur due to issues we can’t control, like material availability, we will stay diligent and do our best to meet our deadlines.

Step 5: Testing The Machine. After it’s completed, we will meticulously test every part of the machine to make sure that everything runs as intended. We thoroughly test it for performance, safety and compliance.

Step 6: Installing The Machine In Your Facility And Discussing Future Needs. When everything is good to go, we transport the finished OEM machine build to your facility and install it so you can begin using it right away.

However, we know that our work doesn’t stop there. You might wonder, “What if my machine breaks, needs an upgrade or doesn’t work as intended?” Our team will always be here if you need to maintain or alter your machine in any way.

Creating Custom Machine Solutions With OEM Specialists

Customised machine solutions can be a dream come true, efficiently creating your products exactly to your specifications.

Are you ready to start? Do you have any other questions or concerns? Call us on +64 784 93246 or message us online.

Echo Automation: Let’s design and build the perfect machinery for you.