Our Services

HMI Design For Operational Control - Human-Machine Interface

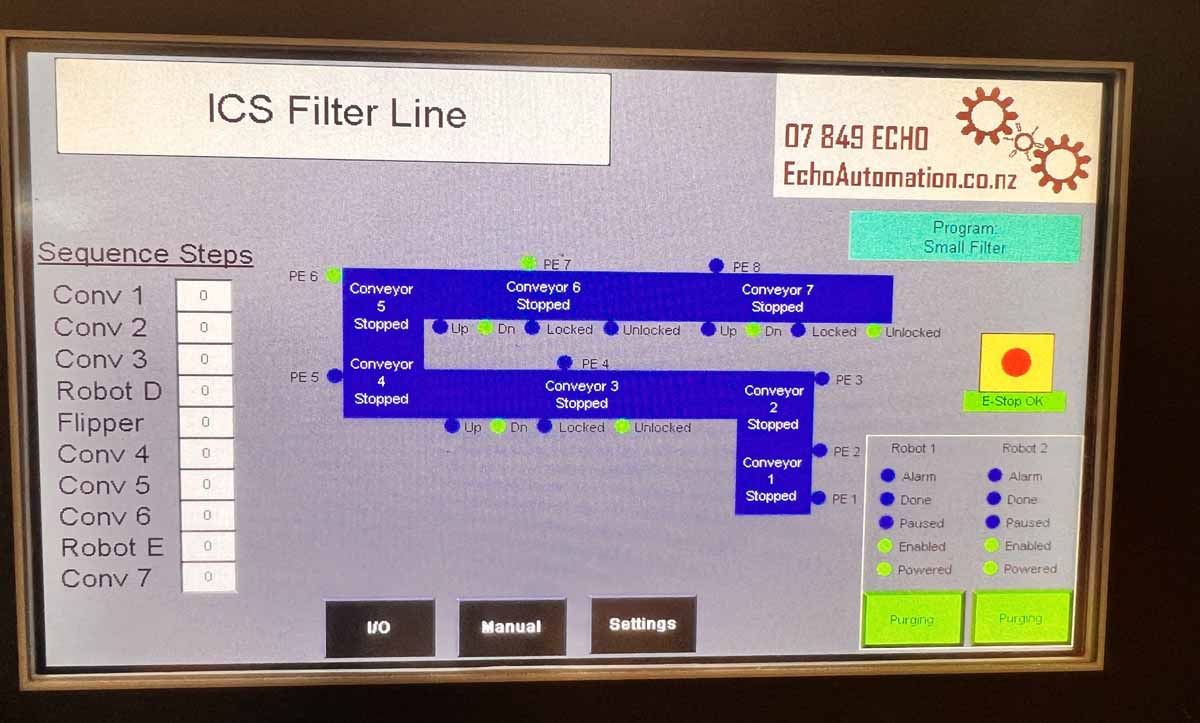

Professionally implemented Human-Machine Interface (HMI) Design is a major contributor to efficient, safe, and profitable industrial operations. Echo Automation specialises in providing HMI solutions that enable intuitive control, real-time monitoring, and a streamlined production environment. Our design approach is grounded in proven methodology, extensive industry knowledge, and a commitment to optimising user experience. The result is a powerful platform that supports data-driven decision-making and ensures operators maintain complete command of industrial processes.

Our solutions integrate seamlessly with a variety of control and data acquisition systems, enabling immediate access to key operational insights. By reducing complexity and focusing on clarity, HMI designs promote faster response times and minimise the potential for human error. This way, industrial plants of any scale gain the ability to operate with heightened reliability and performance.

Why Choose Us ?

Partner with Echo Automation for Innovative HMI Design

Echo Automation is dedicated to advancing modern design through careful planning and modern technology. Our team collaborates closely with your organisation, integrating design best practices and tailored functionality to produce an interface that reflects your operational needs. Instead of pushing standard solutions, we take a holistic approach. This means that every layout, colour scheme, and control sequence is shaped by your unique priorities. From large-scale manufacturing plants to smaller facilities, our expertise covers a broad spectrum of industrial settings.

We stand apart by offering ongoing support and consultation. Our team remains involved through all phases, including conceptualisation, implementation, and maintenance. This approach allows you to harness the maximum potential of your HMI, day after day, without concerns regarding future technology shifts. Echo Automation’s track record in industrial HMI design places us in a leading position to add tangible value to your operations.

Understanding HMI Design in Modern Industries

Human Machine Interface design refers to the creation of interfaces through which operators interact with industrial systems. Contemporary HMI design extends beyond aesthetic appearance or basic data presentation. Modern interfaces require intuitive navigation, accurate real-time data, and advanced safety alerts that guide the user to respond quickly. With ongoing developments in automation, efficient HMI design underpins operator effectiveness and promotes a heightened level of situational awareness.

Industrial HMI design focuses on tangible operational benefits, enabling operators to monitor production lines, conveyor belts, robotic arms, or other machinery with simplicity. There is no tolerance for confusion in a high-stakes environment where downtime and inaccurate data can lead to financial and operational impacts. By employing HMI screens that highlight crucial variables and present process flows in logical structures, decision-making becomes more straightforward and confidence grows.

HMI design solutions from Echo Automation provide:

- Clearly illustrated machine states

- Integrated process visualisations that reflect real-world layouts

- Scalable interfaces capable of handling extensive data streams

- Unambiguous alarm indicators with assigned priorities

Through each of these attributes, Echo Automation’s solutions improve productivity and operator well-being.

Key Elements of An Effective Interface

A robust HMI system ensures the operator always knows the status of the machinery or process being supervised. Echo Automation applies several best practices when crafting interfaces. By doing this, we guarantee that clients receive dependable, user-friendly interfaces that contribute to both safety and performance.

Colour Schemes for Clarity

Colour selection is a vital choice that directly affects an operator’s ability to process important information. An appropriate background colour reduces eye strain and emphasises process variables or alerts. By using muted tones for static components and brighter tones for anomalies or urgent states, operators can distinguish critical data with minimal cognitive load.

Layout Principles

Industrial HMI relies heavily on logical layout. The layout communicates the flow of raw materials, utilities, or energy within a plant. A top-level screen often shows the major systems and their immediate statuses. Secondary screens can focus on more detailed subsystems and highlight any support equipment, such as pumps or smaller instrumentation. This layered structure prevents information overload and helps operators locate relevant data in the shortest time.

Real-Time Data and Intuitive Controls

Effective HMI design requires real-time data that is presented in a comprehensible, operator-centric format. Numeric data is supported by graphical indicators, trends, or bars, all of which help the operator recognise unusual process changes. Instead of reading lengthy tables, the operator sees a clear visual snapshot of performance.

Benefits of Professional HMI Design

Industrial environments can be challenging, with complex processes and strict regulations. A professional approach to HMI design helps streamline procedures and keep operators fully informed. The following are key benefits that echo the importance of this practice:

Clear dashboards, prompt alerts, and structured command inputs make it far easier to address operational upsets. By removing uncertainty, HMI design minimises human error.

Faster operator response to abnormal conditions leads to fewer production interruptions. Advanced interface elements accelerate troubleshooting and help teams restore operations faster.

A carefully thought-out design supports operators in working efficiently. They complete tasks sooner when the interface is easy to navigate and interpret.

Operators and managers can spot production trends early. Visual indicators help assess performance over time and plan improvements, which is an integral part of remaining competitive.

Professional HMI design offers the flexibility to include more functions or connect new equipment. Expansions are easier because the interface is built upon a consistent, modular framework.

Our Approach to Industrial HMI Design

Echo Automation employs a systematic process to ensure that every design aspect aligns with operational objectives. By blending industry expertise with a rigorous approach, we create HMIs that satisfy performance, safety, and user experience needs.

Requirements Gathering

Before development begins, we collect and analyse your operational requirements, focusing on how operators interact with machinery, what data they need, and existing control system constraints. This phase sets the foundation for the rest of the project and ensures we incorporate all essential aspects.

Tailored Interface Creation

Once we have captured the requirements, we move into the design phase. We produce carefully structured layouts to reduce visual clutter, display meaningful data, and maintain consistent flow across screens. Colours, fonts, and icons are chosen based on best practices in industrial HMI design, with particular attention given to brand alignment, safety, and ease of use.

Testing and Refinement

We validate our designs through a multi-stage testing regime. We verify that process variables respond accurately within the interface, that alarms are triggered and displayed properly, and that the overall layout aligns with operator expectations. We gather operator feedback before final deployment, making adjustments for further refinement. This cycle of testing and improvement assures a stable, functional, and operator-friendly interface.

Integration with Existing Systems

A robust HMI solution is not an isolated component. It must communicate smoothly with Programmable Logic Controllers (PLCs), industrial sensors, data historians, and other plant systems. We ensure that our HMI design is adaptable to multiple hardware and software platforms commonly found in the manufacturing industry. Our multi-level integration experience covers a wide range of protocols, such as Modbus TCP and RTU, among others.

Through proper integration, operators can observe and control multiple production lines from the same panel. This reduces the complexity of monitoring separate screens or physically walking across the plant to gather information. Our team configures the HMI to gather critical tags and operational statuses in real time, enabling direct oversight of diverse equipment from a centralised dashboard.

Future-Proof HMI Solutions

Industrial systems evolve over time, making it vital for HMI solutions to adapt. We foresee these changes and include expandability features from the outset. Whenever new machinery, sensors, or entire process lines are introduced, our HMI design is prepared to incorporate additional screens, data points, or alarm configurations.

We also recognise that remote access is increasingly significant in modern industrial environments. By combining secure network strategies and mobile-friendly design, Echo Automation paves the way for managers and operators to oversee critical parameters from tablets or offsite workstations. This has an impact on efficiency because remote oversight reduces response times and fosters continuous improvement.

Choose Echo Automation for Exceptional HMI Design

Echo Automation was established in 2014 with a commitment to bridging gaps in industrial automation. Through continuous investment in people and technology, we have grown into a leader in automation, robotics, and electrical services. HMI design remains a core focus within our offerings, tied strongly to our expertise in system integration, PLC programming, and instrumentation.

Our background includes a wide range of industrial projects, from dairy processing facilities and conveyor lines to more sensitive environments like honey production or hazardous areas. This breadth of experience has deepened our appreciation for consistent, accurate, and user-focused design. At Echo Automation, we never stand still. We continually explore new automation methods, introducing advanced solutions that align with client objectives.

Elevate Your Operations with Echo Automation

Industrial HMI design is an essential element of optimised operations. By prioritising intuitive navigation, meaningful colour usage, and precise control functions, Echo Automation builds interfaces that transform how production lines and entire plants are managed. This approach is grounded in the belief that well-defined HMI design offers more than convenience. It serves as an essential tool in protecting operator safety, ensuring product quality, and minimising downtime.

We stand ready to collaborate on creating an Interface that meets your exact requirements. Our specialist team brings in-depth knowledge of best practices, attention to detail, and a forward-thinking perspective for long-term success. Modern facilities depend on user-friendly systems that present complex data in a clear, actionable format. Through our focus on industrial HMI design, we stand ready to guide your facility on the path to operational excellence.

Contact Echo Automation today to learn more about our approach, or to arrange a consultation. Our dedication to innovation, efficiency, and user satisfaction remains at the core of every project. Let us unify your operations with a powerful, well-structured HMI design that shapes the future of your production environment.